Bolt Tensioner Application

-

50% Tool Coverage

-

100% Tool Coverage

Important formula

| Residual Bolt Load | Bolt Stress x Bolt Tensile Stress Area (Bolt Stretch x Modulus of Elasticity x Bolt Tensile stress area)/ Effective Length. |

|---|---|

| Bolt Tensile Stress Area | (3.14 x D X D) / 4 (D is smallest Stress Dia of Bolt) |

| % of Yield Strength | (Bolt Stress Required / Yield Strength of bolt) x 100 |

| Hydraulic Pressure | (Residual Bolt Load x Load Relaxation Factor) / Hydraulic Area of Load Cell. |

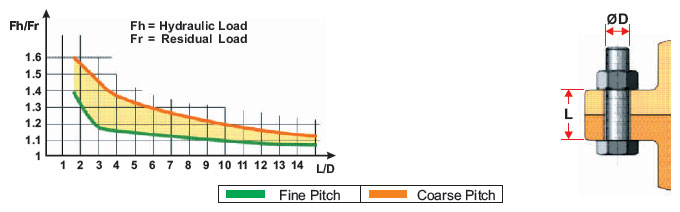

| Load Relaxation Factor | 1.01 + (Bolt Size (Dia.) / Effective Length) or 1.1 which ever is greater. |

Basic Calculation and Working

- Calculate Bolt Residual Load: Residual Load can be calculated from known stress or bolt stretch requirement.

- Calculate Load Relaxation factor using Bolt Dia and Effective Length. It can be calculated from below formula / Chart.

- Calculate application hydraulic load.

- Calculate hydraulic pressure for required hydraulic load.

- Select Tensioning Procedure. (25%, 50%, 100%...etc.)

- Calculate pass load as applicable. (Max applied load should never exceed 95% bolt yield strength).

Useful Conversions

| Area | 1 millimeter2 (mm2 ) = 0.00155 inch2 1 centimeter2 (cm2 ) = 0.155 inch2 |

1 inch2 = 645.16 mm2 1 inch2 = 6.4516 cm |

|---|---|---|

| Load (Force) | 1 Metric Ton (mt) = 1.10231 Short Ton (US) 1 Kilo Niwton, kN = 224.8089 lb 1 Metric Ton (mt) = 9.8066 kN |

1 mt = 0.9842 Long Ton (UK) 1 kN = 0.0958 mt 1 st = 0.0958 mt |

| Pressure | 1 Megapascal (MPa) = 10 Bar 1 Kg per cm2 (Kg/cm2 ) = 0.98066 Bar |

1 bar = 14.5037 psi 1 bar = 1.0197 Kg/cm2 |

| Pressure | 1 Megapascal (MPa) = 10 Bar | 1 bar = 14.5037 psi |