Features of Impact Sockets

Features of Impact Sockets, Accessorise and Socket Sets

- Standard, Deep and Thinwall Sockets

- Up to 3.1/2" square drive Impact Sockets through to 235MM (9.1/8") across the flats

- # 5 spline drive to 80mm (4") across the flats

- Wide variety of Accessories

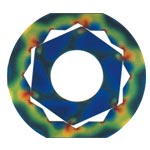

Freecorner PROFILE

The Freecorner profile is provided on the square drives as well as on the hexagon end of Impact Sockets 1/2" square drive and above.

CONVENTIONAL PROFILE Corner point contact high stress areas

Highlights show contact points on the corner of the fastener

FREECORNER PROFILE Distributed surface loads relieves possible stress area

Highlights show contact points away from the corner of the fastener

Why Powermaster Impact Sockets

- All Impact Sockets are made from high strength alloy steel.

- All Impact Sockets are heat treated for the best combination of strength and impact resistance.

- All Impact Sockets have an optimum wall thickness for strength and access on fasteners having restrictions.

- The depth of the Hex openings is designed to accomodate the full standard fastener head.

- All Impact Sockets have chamfered openings for ease in engagement with the drive tool and the fastener.

- Concentric openings and large clearance holes to meet industrial specifications.

- All Impact Sockets have a Ring-N-Pin arrangement for securing them to the drive.

- Sockets are plated and black oxidized coated for increased protection from rusting.

The benefits of the Freecorner profile include are

- Reduced risk of fastener rounding.

- Increased chances of turning worn fasteners.

- Elimination of high stress concentration points increasing the impact resistance and the torque transmitting capability.

Safety Notice

Always use safety goggles when using impact equipment.